Fully automated semi-solid preparation compounding

The gako unguator range

The unguator technology

The gako product line is based on the Unguator Technology patented by Gako Deutschland GmbH, Germany. The core of the technology is to comply with requirements of prescribed semi-solid formulations. It consists of the patented arrangement of the Mixing Blade and the jar that serves as both, a hygienic mixing jar and a hygienic dispensing jar. The principle of the preparation method using technology in the closed gako unguator mixing system is quick and easy to learn, true to the motto: "learning by doing". A little experience will make it easy to prepare all semi-solid formulations. Using the technology enables the pharmacy to better prepare prescription ointments in a shorter period of time, compared to the conventional methods. For the first time, it is possible to not only standardize individually compounded ointments, but also to validate them, too - complying GMP.

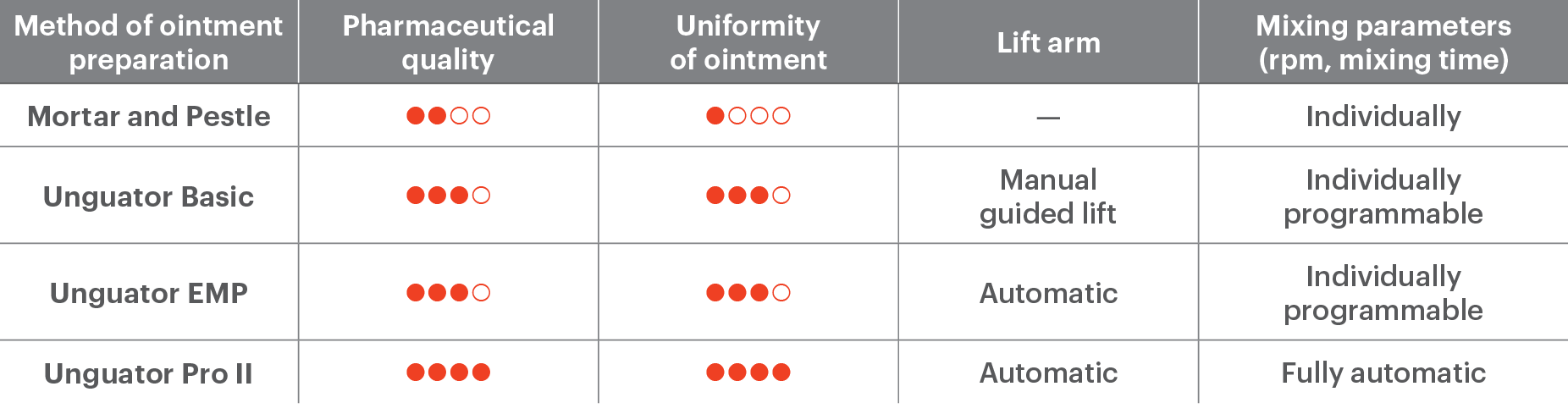

The current gako unguator devices - gako unguator BASIC, EMP and PRO II - are useful and advanced improvements. The gako unguator devices feature a high safety standard. The devices are manufactured by Gako Deutschland GmbH, Schesslitz - Germany. With increased product quality, product uniformity and reproduction of ointments prepared individually and in batches were vastly improved.

The gako unguator devices

Semi-solid preparation compounding

gako unguator BASIC

Semi-solid preparation compounding

gako unguator EMP

Fully automated Semi-solid preparation compounding