Specifications

Single-step process uniting mixing,

and deaeration

It can be used on its own or in a combined workflow with other compounding equipment, such as the gako unguator or other devices or molds required for the preparation of semisolids or molded dosage forms.

Advantages

- Single-step process uniting mixing, wetmilling, and deaeration

- Dosage accuracy

- High speed

- Ideal for hazardous drugs

- Suitable with thermolabile APIs

- Closed environment

- Reduces air contact

- Avoids microbial contamination

- Conservation of resources

- Precise time setting

- Compact design

- User-Friendly

- Quiet operation

Single-step process

For pharmacists who are looking for a simple, fast, and affordable solution for mixing, deaeration, and wetmilling, the gako PM140 is a revolutionary device that combines those functions in a single-step to standardize the compounding process, ensuring safety, quality, and efficacy for compounded preparations while saving time and money for the pharmacy.

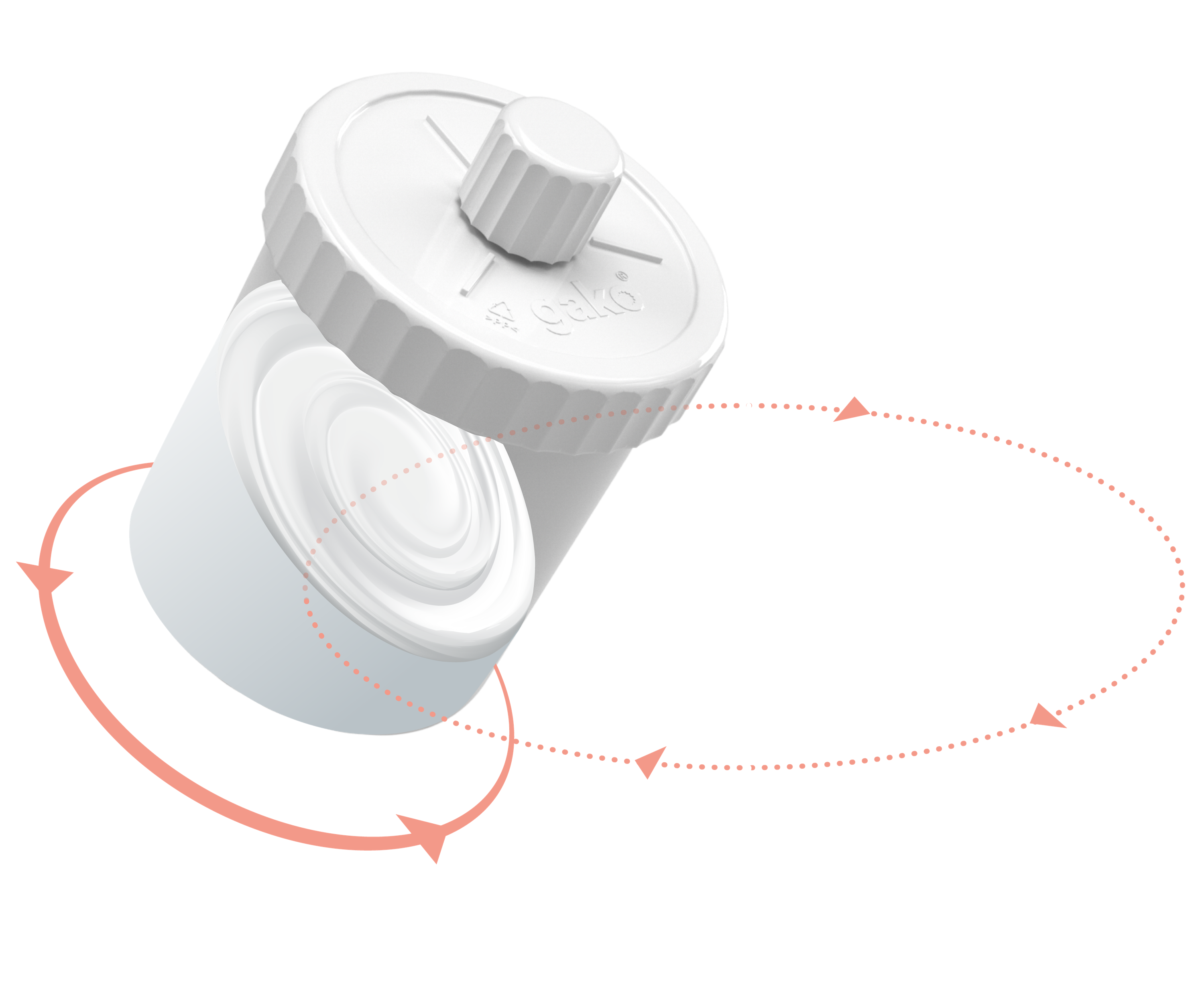

Mixing

Introducing the gako PM140 - a user-friendly device for preparing formulas in under 60 seconds! With its closed mixing jar and no need for blades, it ensures content uniformity and stable emulsions. Say goodbye to formulation issues like creaming, sedimentation, flocculation, and coalescence. Achieve perfect homogenization for optimal rheological properties.

Deaeration

The gako PM140 deaerates emulsions, gels and ointments in 45 seconds, ensuring the removal of macro-bubbles from those formulations.

Reproducible and easy operation

- either in seconds: 10, 20, 30, 40, 50, 60 or 90

- or in minutes: 2, 3, 4, 5, 10 or 15

- reproducible mixing time

- easy documentation of your mixing process

- insert the PM mixing vessel

- close the lid

- press start

- automatic stop after set duration is done

Workflows

standalone or with other equipment

The gako PM140 can be used on its own or in a combined workflow with other compounding equipment, such as the gako unguator or other devices or molds required for the preparation of semisolids or molded dosage forms.

The gako PM jar 100ml HV is a sterile and disposable mixing jar made of polypropylene, designed for deaeration and mixing of gels, creams, and ointments.

Special features

The gako PM jar 100ml HV features a movable bottom that allows for easy elimination of remaining volume by pushing it upwards, minimizing air exposure.

It is also compatible with gako unguator devices, enabling it to be used with low-soluble APIs and to prepare suspension formulas. It, therefore, eliminates the need to transfer the compound from the gako unguator jar to the gako PM jar 100ml HV.

As the jars are disposable, they can serve as primary packaging, streamlining compound delivery to patients, reducing the number of tools to clean, saving time, and preventing material loss during transfers.

Optimal Capacity and Performance

With a mixing capacity of up to 100 ml, it provides an internal nominal volume of 140 ml to facilitate particle movement and enhance its performance during the process.

Heat Resistance and Safety

It demonstrates heat resistance of up to 85°C, allowing for safe use in hot water baths when heat application is necessary for the formulation. You can rely on this jar for efficient and secure compounding procedures.

- Movable bottom, reducing air contact

- Applicable high-viscosity compounding

- Designed to be performed in mixing and deaeration processes

- Compatible with gako unguator

- Sterile, indicated by the sterile|EO label

- Convenient as a primary packaging option

- Heat resistance up to 85°C in hot water baths

The gako PM jar 125ml HV+LV is a specially designed mixing jar for low-viscosity preparations. It is a sterile and disposable jar, ensuring the highest standards of hygiene and convenience.

Multiple Applications

This jar is primarily intended for mixing fluid formulas. However, it is also suitable for other preparations such as creams, ointments, and gels. Its versatility makes it a valuable tool for various compounding processes.

Optimal Capacity and Performance

With a mixing capacity of up to 125 ml, the gako PM jar 125ml HV+LV provides an internal nominal volume of 180 ml. This design allows for better particle movement and enhances performance during the compounding process.

Heat Resistance and Safety

The gako PM jar 125ml HV+LV demonstrates heat resistance of up to 85°C, making it safe for use in hot water baths when heat application is necessary for the formulation. You can rely on this jar for efficient and secure compounding procedures.

- Presence of stable bottom for steady handling

- Suitable for mixing, wetmilling, and deaeration processes

- Ideal for suppository preparation

- Applicable to both low- and high-viscosity formulations

- Sterile, indicated by the sterile|EO label

- Convenient as a primary packaging option

- Heat resistance up to 85°C in hot water baths